Monitoring, Standards, and Quality Control of the Dairy Industry

This article provides an in-depth exploration of the dairy industry, covering essential processes, meticulous monitoring, compliance with standards, and the pivotal role of optimization in ensuring quality and efficiency. It offers valuable insights for industry professionals, researchers, and regulatory bodies invested in understanding and advancing the dynamics of dairy production.

In the dairy industry, the journey of milk from farm to final products involves meticulous sampling and analysis to ensure quality and compliance with hygiene and food standards. While fresh milk has a short shelf life, milk powders have extended the reach of dairy products globally. The adoption of new practices, including automation, robotics, and advanced sensing technologies, is transforming the traditional dairy industry by enhancing operational efficiency and optimizing the supply and production chains.

1. Introduction

The dairy industry focuses on optimizing milk processing to prolong shelf life and maintain quality. Facing volatility in global prices and changing consumer demands, dairy producers are compelled to innovate and improve their production processes. The world’s leading milk producers are adapting their practices to meet the diverse nutritional content and standards across different countries.

2. Milk Processing

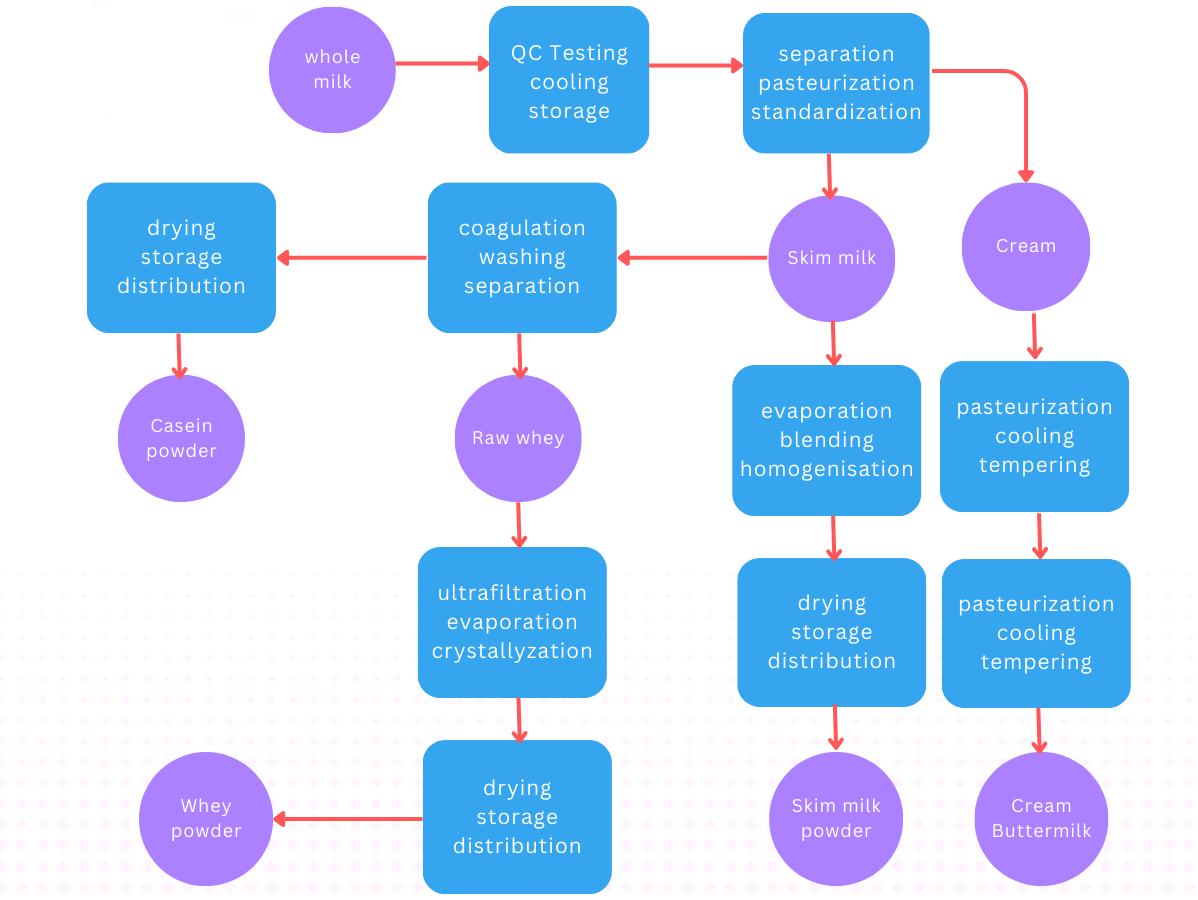

Figure 1 illustrates the milk processing flow diagram at the dairy plant. Upon arrival at the facility, milk is weighed using a weighbridge, and the weight is automatically recorded. Simultaneously, an on-board computer wirelessly transfers data to a capture system, documenting the temperature and volume of milk from each farm. It is essential to maintain a temperature range of 4–6°C during this process.

To ensure quality, sterile containers automatically collect milk samples from each supplier at the source. These samples are then sent to a laboratory technician for thorough analysis. Any deviation in composition, taste, or smell from the standard results in a lower quality rating. The laboratory conducts tests on each sample for acidity, antibiotics, added water, fat, and protein content. The analytical tests adhere to international standards outlined in Table 1, guiding the overall quality control process.

|

Quality tests |

Acceptable limits |

Standards |

|

Acidity (Titratable) |

<=0.18% |

ISO 6091:2010 |

|

Antibiotic residues |

Absent/0.1 g |

ISO 26844:2006c |

|

Freezing point (added water) |

−0.54°C |

ISO 5764:2009 |

|

Fat |

0.8% |

ISO 1736:2008 |

|

Protein |

34% |

ISO 8968–1/2:2014 and ISO 14891:2002 |

|

Lactose |

>4.2% |

ISO 22662:2007 |

Testing Microbial Quality at Milk Intake

Before the milk is accepted for processing, it undergoes microbial quality testing at the intake point. A historic method known as the Resazurin test, dating back to 1929, is used to assess the milk’s microbiological quality. The test involves adding a small amount of milk and a solution of Resazurin dye, then incubating the mixture at 37°C. The resulting color change is compared to standardized color disks or measured using a Comparator instrument. Additionally, milk density testing is carried out as a rapid method to detect any adulteration or deviations from normal milk composition, such as dilution with water or skimming. This test involves using a dipping lactodensimeter combined with a thermometer, calibrated to measure density within specific ranges for standard milk.

3. Dairy Processing Stages

Upon successful completion of initial analytical tests, the raw milk carried in the milk container truck advances to the whole milk intake bays. The driver connects the milk hoses, and the milk is then pumped into expansive bulk storage tanks known as milk silos, with capacities reaching up to 300,000 liters. To initiate the pumping process into the whole milk silos, the driver inputs the truck's identification number on the pump's control panel or employs a key fob—a passive wireless electronic device utilizing radio frequency ID technology.

As the milk is unloaded, an automatic cooling system brings it down to 4–6°C through a heat plate exchanger (HPE) during the pumping process into the silo. Opportunities for implementing processing monitoring arise during the setup and offload times, particularly when coupling and decoupling the milk intake hoses. The variability in pumping time serves as a performance indicator specific to each pump, with flow rate representing a reliable metric.

Several factors can influence pumping time, including the volume of milk in the receiving silo, the number of bends and valves in each pipeline, and associated backpressure variations. Achieving process optimization during milk offload involves ensuring the pumps operate effectively and efficiently, as well as planning truck supply through intelligent time slot management.

3.1. Separation, Clarification, and Centrifugation

Milk processing plants typically have their own unique processes, including steps such as clarification, separation, and centrifugation. Upon arrival at the dairy, milk often needs to be clarified to remove impurities like dirt particles and precipitated protein, which can protect downstream processing equipment. Centrifugation and microfiltration techniques are commonly used to remove bacteria, spores, and somatic cells from milk, including leucocytes, reducing the presence of harmful substances and improving the overall quality and safety of dairy products.

Centrifuges are primarily used in dairy processing plants for hot milk separation, separating milk fat from skim milk in a process known as skimming. The fat content of the cream can be controlled to a specific level using an in-line fat standardization system. Different types of centrifugal separations, such as clarifiers and separators, serve specific functions in the dairy industry, including removing solid particles, separating cream, and eliminating bacteria. The standardization of milk involves adjusting the levels of fat and solids-not-fat to create a uniform milk fat content in various dairy products for consumer and commercial purposes.

3.2. Pasteurization

Initially developed to control tuberculosis-causing Mycobacterium bovis, pasteurization is no longer necessary for this purpose due to annual testing and removal of cows affected by TB. However, to combat microorganisms like Coxiella burnetii, which causes Q fever in humans, milk must be pasteurized at 161°F (71.7°C) for 15 seconds. The standard vat pasteurization process involves heating milk to 63°C (145°F) for 30 minutes.

Verification of Pasteurization Process

The PasLite test is widely used to confirm the adequacy of milk pasteurization for various dairy products. This test identifies alkaline phosphatase, a natural milk enzyme that is eliminated during pasteurization. The test takes just 3 minutes, allowing multiple samples to be processed simultaneously, although readings are done one at a time. This rigorous process ensures the safety and quality of dairy products for consumption.

4. Milk Powders

Milk powders have significantly boosted the dairy industry’s global reach. The process of making milk powder includes evaporation and spray-drying techniques, which must be carefully controlled to prevent damage to the nutritional and functional quality of milk.

4.1. Evaporation and Drying

Milk powder is created by spray-drying pre-condensed milk, often using a falling film evaporator to concentrate the milk from around 13% total solids (TS) to a target of up to 52%. Evaporation involves removing water from the milk, with the process carefully managed to avoid heat damage to the proteins and achieve the desired concentration. Energy efficiency is a key consideration in evaporation design, with the process often taking place in a vacuum at specific pressures and temperatures to minimize thermal impact.

After evaporation, the milk is passed through a spray dryer where it is atomized into small droplets. The drying chamber’s hot and low humidity environment helps evaporate the water from the droplets, resulting in milk powder. The particle size and bulk density of the powder are important factors influencing its reconstitution properties and how it dissolves in liquids. The heat treatment received by the milk powder, measured by the Whey Protein Nitrogen Index (WPNI) and casein number, affects its quality and characteristics.

Milk powders are regulated in terms of composition and additives, with standards set by the Codex Alimentarius Commission. Controlling the moisture content of milk powder is crucial for long-term quality and production cost. Various methods for determining moisture content exist, including reference methods and newer techniques designed to minimize interference from air humidity.

5. Microbiological Quality Analyses

At every stage, the milk is at risk of contamination from equipment, air, and water, necessitating rigorous microbial analyses from farm collection to the final packaging stages.

5.1. Microbial Quality Analysis at Farm Level

From the point of collection on the farm, the microbial quality of milk is managed. On-farm tests like the Mastitis Test help in early detection of infections.

5.2. Microbial Quality Testing at Milk Intake

Advanced testing on milk arrival at processing facilities ensures it meets required standards before entering the production line.

6. Microorganisms and Milk

The diversity of microorganisms in milk requires comprehensive testing protocols to ensure that harmful bacteria are managed effectively throughout processing.

7. Dairy Industry technologies

The dairy industry is gradually adopting new technologies, both at the farm level and in dairy processing plants. For instance, robotic milking systems, such as those developed by Lely and Delaval, have increased milk productivity by allowing cows to enter the milking parlor without prompting. These systems integrate data from cow tags, tracking metrics like steps and feeding behavior. Additionally, technologies like MooCow and MooMonitor help monitor cow heat cycles and guide them in the milking parlor. Other innovations, like the MooCall sensor, can even detect when a cow is about to give birth and alert the farmer via SMS.

Furthermore, advanced analytical instruments for milk analysis, such as Fourier transform MIR spectroscopy, flow cytometry, ELISA, PCR, gas chromatography/mass spectrometry, liquid chromatography/electrospray ionization, and ICP-MS, are being introduced to enable detailed milk analysis for various purposes including quality control and health monitoring.

8. Conclusion

The dairy industry’s commitment to quality and safety from farm to finished product requires robust process controls and adherence to global standards. Amid alternative milk preferences and a growing lactose-intolerant population, the industry is adopting new innovations to remain competitive and meet the highest safety and quality benchmarks. Despite these trends, milk and dairy products remain essential global commodities.

Read More: Probiotics: Improving Gut Health and Supports a Healthy Immune System

To contact the kalber Dairy Export Department, please refer to the Contact Us section.

Ref:

The Dairy Industry: Process, Monitoring, Standards, and Quality | IntechOpen

-min(1).webp)

(2).webp)

.webp)