Most Common Emulsifiers and Stabilizers in the Food Industry

Explore the most widely used emulsifiers and stabilizers in food processing. Learn how they improve texture, shelf life, and quality in dairy, bakery, and processed foods.

In modern food manufacturing, texture, consistency, and stability are just as important as taste. To achieve these qualities, emulsifiers and stabilizers are widely used across various sectors—from dairy and baked goods to sauces and frozen desserts. This comprehensive guide explores the most common types of food emulsifiers and stabilizers, their differences, functions, and how they improve product quality and shelf life.

What Are Emulsifiers?

Emulsifiers are compounds that help mix two or more immiscible substances like oil and water, creating a stable and homogeneous product. Without emulsifiers, products like mayonnaise, margarine, and ice cream would separate quickly and lose their appealing texture.

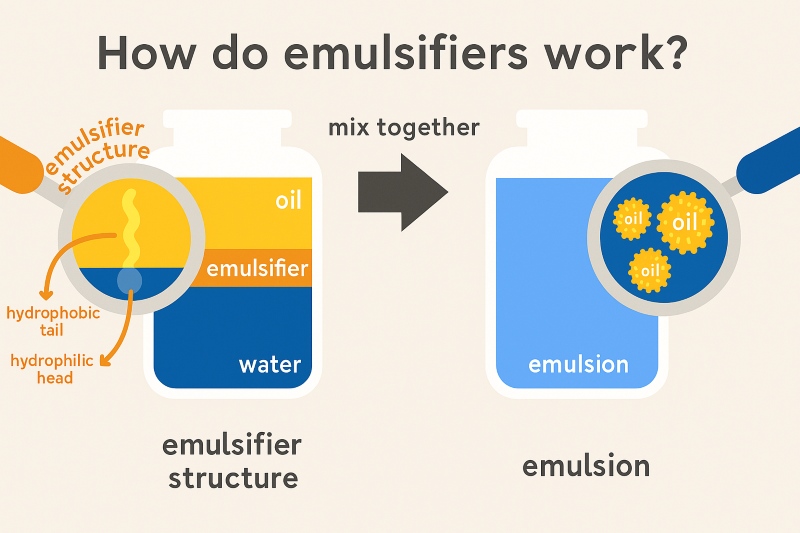

How Emulsifiers Work

Emulsifiers contain both hydrophilic (water-loving) and lipophilic (fat-loving) ends. This dual nature allows them to sit at the interface of oil and water droplets, reducing surface tension and stabilizing the mixture. By doing so, they prevent the separation of immiscible liquids such as oil and water, forming a uniform and stable emulsion.

When added to dairy products, emulsifiers align themselves between the fat and water phases, forming a protective layer around fat globules. This not only improves texture and consistency but also extends shelf life by resisting creaming, coalescence, or syneresis. Whether it's in milk-based beverages, yogurt, or cream, emulsifiers play a key role in maintaining a smooth, homogeneous product with an appealing mouthfeel.

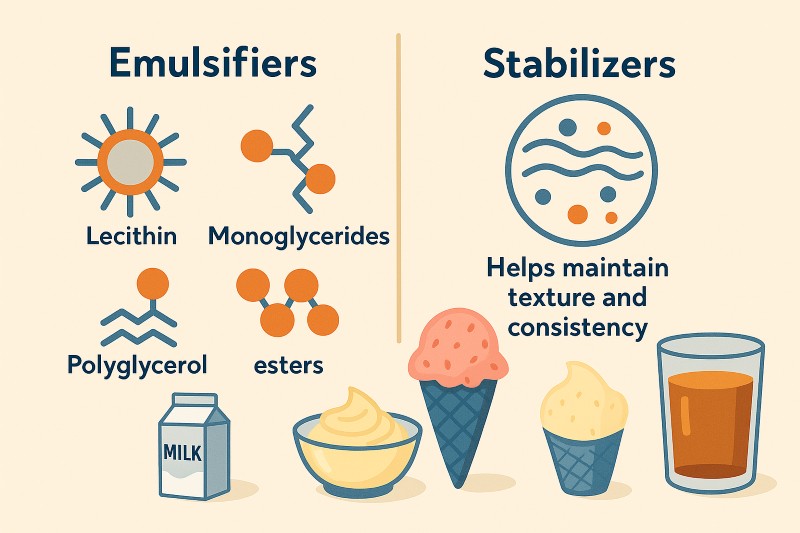

Common Food Emulsifiers and Their Applications

Emulsifiers are essential ingredients in many food products, especially in the dairy and confectionery industries. They help blend ingredients that normally don’t mix, like oil and water, ensuring consistency, stability, and a smooth texture. The table below highlights some of the most widely used food emulsifiers, along with their E numbers, typical applications, and key notes about their sources or functions.

|

Emulsifier |

E Number |

Applications |

Notes |

|

Lecithin |

E322 |

Chocolate, margarine, bakery |

Derived from soy, eggs, or sunflower |

|

Mono- and Diglycerides |

E471 |

Bread, cakes, ice cream |

Common in fat-rich foods |

|

Polysorbates (e.g., Polysorbate 80) |

E433 |

Ice cream, whipped toppings |

Improves smoothness and overrun |

|

Sorbitan Esters |

E491–E495 |

Pastries, confections |

Often used in synergy with polysorbates |

|

Sucrose Esters |

E473 |

Coffee whiteners, sauces |

Natural sugar-derived |

|

PGPR (Polyglycerol polyricinoleate) |

E476 |

Chocolate products |

Enhances flow and reduces fat content |

Emulsifiers in the Dairy Industry

In dairy products, emulsifiers improve:

- Texture of cheese spreads and processed cheese

- Creaminess in milk-based beverages

- Stability in ice cream and whipped cream

For instance, mono- and diglycerides are used to reduce ice crystal formation in frozen dairy desserts, improving mouthfeel and shelf life.

What Are Food Stabilizers?

Stabilizers are substances that help maintain a food product’s physical and chemical structure. Unlike emulsifiers, they don’t mix ingredients, but instead keep them from separating over time.

They are crucial in suspending particles, preventing ice crystal growth, and retaining emulsions once formed.

Common Food Stabilizers and Their Uses

|

Stabilizer |

E Number |

Source |

Application |

|

Carrageenan |

E407 |

Red seaweed |

Dairy desserts, chocolate milk |

|

Xanthan Gum |

E415 |

Fermented sugar |

Salad dressings, gluten-free bakery |

|

Guar Gum |

E412 |

Guar beans |

Ice cream, sauces |

|

Locust Bean Gum (Carob Gum) |

E410 |

Carob tree seeds |

|

|

Pectin |

E440 |

Fruit peels |

Jam, jelly, yogurt |

|

Sodium Alginate |

E401 |

Brown algae |

Reformed meats, desserts |

|

Gelatin |

— |

Animal collagen |

Marshmallows, yogurts |

Functional Benefits of Stabilizers

- Improved mouthfeel and creaminess in low-fat dairy

- Suspension of particles in flavored milk

- Freeze-thaw stability in frozen desserts

- Gelling and thickening for jams, jellies, and yogurts

Emulsifiers vs. Stabilizers – What's the Difference?

Although emulsifiers and stabilizers are often used together in food formulations, they serve distinct functions. Emulsifiers primarily help mix oil and water, forming stable emulsions, while stabilizers work to maintain that stability over time by thickening the mixture and preventing separation. The comparison below outlines the key differences between these two important ingredient types.

|

Feature |

Emulsifiers |

Stabilizers |

|

Primary Function |

Mix oil and water |

Maintain product consistency |

|

Type of Action |

Surface-active agents |

Viscosity modifiers |

|

Used In |

Mayonnaise, chocolate, ice cream |

Yogurt, jelly, sauces |

|

End Effect |

Stable emulsion |

Prevents separation or syneresis |

Tip: Some ingredients like lecithin or xanthan gum may play both emulsifying and stabilizing roles depending on the formulation.

Use in Bakery and Processed Foods

- In bread and cakes, emulsifiers improve dough strength, volume, and softness.

- Stabilizers like guar gum improve water retention and delay staling.

- In processed meats, stabilizers help retain moisture and improve sliceability.

Clean Label Considerations

With increasing consumer demand for clean labels, manufacturers are shifting to natural or plant-based alternatives:

- Sunflower lecithin as a non-GMO emulsifier

- Pectin from apple or citrus peel

- Tara gum or chia seed gum as novel stabilizers

Using fewer, familiar-sounding ingredients not only improves transparency but also appeals to health-conscious buyers.

Regulatory and Labeling Notes

- Emulsifiers and stabilizers are typically labeled by their E numbers in Europe and by their common names in the U.S.

- Some may be restricted in certain countries or require declaration if derived from allergens (e.g., soy lecithin).

Final Thoughts

Emulsifiers and stabilizers are vital behind-the-scenes players in food formulation. From ensuring that a chocolate bar doesn’t bloom to helping your low-fat yogurt stay creamy, these ingredients are essential to both quality and efficiency in modern food production.

As demand grows for stable, long-lasting, and clean-label products, the strategic use of natural, multifunctional emulsifiers and stabilizers will only increase—especially in sectors like dairy, plant-based, and gluten-free foods.

(2).webp)

.webp)