Everything about the Production, Export, and Purchase of UHT Milk from Iran

Here we discuss the types of milk based on the type of thermal process, the stages of preparing dairy products in the factory, the best famous brands of Iranian sterilized milk, storage time, methods of cold sanitization of milk and export challenges in the industry of this product.

| Table of Contents |

| 1. Compositions of high-fat milk |

| 2. Composition of low-fat milk |

| 3. Processing liquid milk and turning it into different dairy products in a dairy factory |

| 4. Types of milk based on the type of sanitization process |

| 5. Methods of cold sanitization of milk |

| 6. Producers of bulk milk for export in Iran (where to buy bulk uht milk?) |

| 7. Kalber's export products |

| 8. To which countries has long life Kalber milk been exported? |

| 9. Is one liter of Kalber UHT milk available for export or domestic consumption? |

| 10. Which countries are the primary buyers of Kalber's long-life milk? |

| 11. Advantages and estimated value of aseptic packaging |

| 12. Durability of tetrapack 200 cc Kalber milk |

| 13. Import, Export, and Trading of UHT Milk (long lasting milk) |

| 14. Annual export of 3000 tons of Kalber dairy products |

| 15. Average content of SNF in milk |

| 16. PH value of milk |

Milk is a highly nutritious food with a short shelf-life, necessitating careful handling. It is highly perishable because it serves as an ideal medium for the growth of microorganisms, especially bacterial pathogens that can cause spoilage and illnesses in consumers. Processing milk extends its shelf-life for days, weeks, or even months and helps reduce food-borne illnesses.

The shelf-life of milk can be extended by several days through methods like cooling, which significantly influences raw milk quality, or fermentation. Pasteurization, a heat treatment process, further extends milk's usable life and reduces pathogenic microorganisms. First, we get to know the ingredients.

Compositions of high-fat milk

Fat milk is a valuable and complete source of nutritious compounds for humans. Here, we look at the ingredients in full-fat milk. The nutritional value of 100 grams of full-fat milk is as follows:

| value | Main ingredients |

| 3.2 gr | total fat |

| 4.7 gr | carbohydrate |

| 3.3 gr | Protein |

| 4.8 gr | sugars |

| 4.67 gr | Pure carbohydrates |

| 123 milligram | Calcium |

| 12 milligram | magnesium |

| 101 milligram | phosphorus |

| 150 milligram | potassium |

| 1.9 microgram | Selenium |

| 38 milligram | sodium |

| 0.41 milligram | Roy |

| 88.1 gr | Water |

| 12 milligram | Cholesterol |

Composition of low-fat milk

The nutritional value of high-fat milk and low-fat milk does not differ in terms of vitamins, minerals, proteins and hormones. The only difference between them is the amount of calories and fat. There are about 150 calories and 8 grams of fat per 220 grams of full-fat milk, while about 100 calories and 5 grams of fat are found in 220 grams of 1% low-fat milk. The table below shows the amount of calories and fat in different types of milk:

Calories and fat content of milk per 220 grams

| fat | calories | milk |

| 8 gr | 150 | Full fat milk - whole milk |

| 4.5 gr | 120 | 2% low-fat milk |

| 5 gr | 100 | 1% low-fat milk |

Processing liquid milk and turning it into different dairy products in a dairy factory

Processing liquid milk and converting it into various dairy products involves several steps carried out in a dairy factory. Here's an overview of the flow of processing milk into different dairy products, such as milk powder:

-

Collection and Transportation: Raw milk is collected from dairy farms and transported to the dairy factory in refrigerated trucks to maintain its quality and prevent spoilage.

-

Reception and Testing: Upon arrival at the factory, the milk is tested for quality and safety, including checks for temperature, composition, and the presence of contaminants.

-

Clarification and Separation: The milk is clarified to remove impurities and then separated into cream and skim milk using centrifugal separators. This step allows for the production of products with varying fat content.

-

Standardization: The fat content of the milk is standardized to ensure consistency in the final product. This involves adjusting the fat level to meet the desired specifications for different dairy products.

-

Pasteurization: The milk is pasteurized by heating it to a specific temperature for a set period to kill harmful microorganisms, ensuring safety and extending shelf-life.

-

Homogenization: The milk is homogenized to break down fat globules, ensuring a uniform texture and preventing cream from separating.

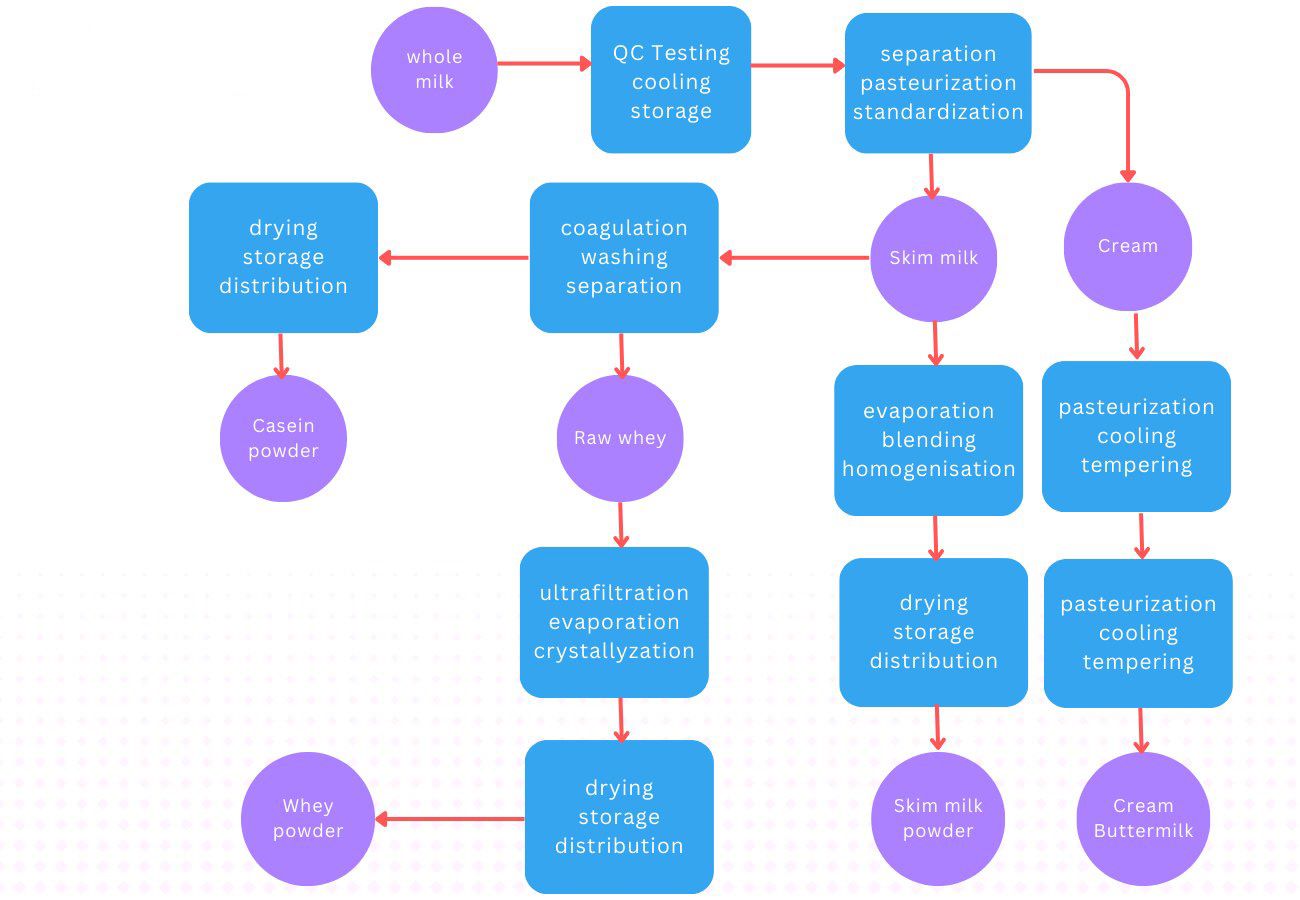

Processing liquid milk turns it into various dairy products such as milk powder, cream, buttermilk, whey powder, and casein powder. The following figure shows the flow of processing milk into different dairy products.

Types of milk based on the type of sanitization process

Types of milk based on the sanitization process include pasteurized, sterilized, ultra-high-temperature (UHT), ultra-pasteurized, or extended shelf life (ESL) milk.

Pasteurization of milk: heating milk to destroy potentially pathogenic bacteria and increase the shelf life of milk is called pasteurization.After heating, the milk is cooled to 3-4 degrees. Heating the milk destroys the harmful microorganisms in it, and cooling it makes the new microorganisms unable to grow and reproduce.

In general, the pasteurization process is done in two slow and fast modes.

63 to 65 degrees for 30 minutes

72 degrees for 15 seconds

85 to 90 degrees for a few seconds

Sterilization of milk: Sterilization is the destruction of pathogenic microorganisms in milk, especially heat-resistant bacteria. Because yeasts and molds are destroyed with the lowest amount of heat or during the pasteurization process, but the destruction of the cell wall of heat-resistant bacteria and their death requires high heat.

110 degrees for 30 minutes

130 degrees for 30 seconds

145 degrees for 1 second

Depending on the type of method chosen, heat may be applied directly or indirectly. After that, the milk is cooled to 20 degrees and packed in sterile containers under completely sterile conditions.

Ultra-pasteurization of milk - UP milk:

There is another type of high-temperature pasteurization, which is called ultra-high temperature pasteurization or ultra-high temperature pasteurization. In this method, milk is heated at 140 degrees Celsius and remains at this temperature for 2 seconds. Then, it is packaged in a sterilized environment. Also, the packaging should be sterilized using hydrogen peroxide. The shelf life of this type of milk is between 30 and 60 days. With the benefit of aseptic packaging, ESL-Extended Shelf Life milk can be stored for up to 90 days at a maximum temperature of 4 degrees Celsius.

In terms of total cost for the producer, the ultra-pasteurization method is less expensive than the ultra-heat method. Although the initial setup of this method is more expensive than the cost of the standard pasteurization method, but using this new milk technology is easier for the producer than the ultra-thermal method. The reason for this relative simplicity is the lower temperature of the process and, of course, packaging with less trouble. There is no need for aseptic packaging and it is sufficient that the environment and equipment are sterilized during packaging.

In order to store milk according to its production process, it is necessary to pay attention to these points:

Storage of pasteurized milk

Pasteurized milk should be kept in the refrigerator at a temperature of 0 to 4 degrees Celsius. The storage time of pasteurized milk is usually 4 to 5 days.

Sterilized milk storage

Sterilized milk can be stored at room temperature for 4 to 6 months, but after opening the package, it must be stored in the refrigerator and consumed within 5 days.

Storage of ultra pasteurized milk

The shelf life of this type of milk will vary from 30 to 60 days.

It should not be forgotten that ESL milk is different from UHT milk or ultra-temperature milk, and it must be kept in the refrigerator even before opening.

Methods of cold sanitization of milk

Due to the small effects of the thermal process on the sensory and nutritional properties, the use of cold methods in food preservation has been considered. Among the most important non-thermal methods used in milk processing, we can mention the following: use of high pressure, vibrating electric field, microfiltration, use of CO2 gas under high pressure and radiation.

The high pressure process helps to make the product healthy by destroying the cell wall and membrane, changing the morphology of cells, denaturing proteins, preventing genetic mechanisms and destroying ribosomes.

Vibrating electric field technology destroys microorganisms by creating holes in the cell membrane.

Microfiltration works by separating microorganisms based on their size and volume differences with the main ingredients of food.

The technology of using CO2 gas under high pressure destroys microorganisms by changing the cell membrane, reducing intracellular pH, inactivating key enzymes, directly affecting metabolism, disturbing the internal electrolyte balance, and removing vital compounds from the cell.

Irradiation also destroys microorganisms by changing biological systems.

Producers of bulk milk for export in Iran (where to buy bulk uht milk?)

Some of the best famous brands of exported sterilized milk in Iran are as follows:

Kalber's export products

With more than 28 years of experience in the field of producing dairy products, Kalber Dairy offers a wide range of products in two different sectors. The B2B collection includes industrial milk powder, whey powder and unsalted butter. The FMCG portfolio also includes various types of cheese, tetrapak milk, tetrapak flavored milk, sterilized cream with a long shelf life, and various types of juice with a long shelf life.

A wide range of milk and dairy products are ready to order and export in Kalbar:

Export cheese:

Kalber exports some kinds of cheese, including feta cheese, cream cheese, labneh, and processed types.

• Tetrapak breakfast cream 200 grams for export:

This product is produced by pasteurizing fresh liquid milk. Kalber export cream includes cream with 200 ml vegetable fat, cream with 200 ml animal fat and cocoa cream.

• 200 cc sterilized uht milk for export:

All kinds of UHT milks (long life milks) of Kalber Dairy are supplied to the domestic and international markets as Full Cream or full fat (3% fat), Half Cream (2.5% fat) and Skimmed or low fat (1.5% fat). Due to the long shelf life of sterilized milk, it can be easily sent to distant destinations.

• Exported flavored UHT milk:

Kalber's flavored sterilized and homogenized milk collection is sold in coffee, banana, cocoa, strawberry and honey flavors.

• Fruit juice for export:

Kalber's range of juices offers a range of refreshing flavors including UHT Pomegranate Juice, UHT Orange Nectar, UHT Grape Juice, UHT Pineapple Juice, UHT Cherry Juice, UHT Apple Juice and UHT Mango Nectar.

Exported butter:

Salted butter or unsalted butter (25 kg) is made from high quality fresh cream using the world's leading butter making technology.

Exported dairy powder:

The category of Kalber dairy powders includes both milk powder and whey powder.

To which countries has long life Kalber milk been exported?

Kalber has exported to various countries including the Middle East, Africa and CIS countries.

Is one liter of Kalber UHT milk available for export or domestic consumption?

The high volume of milk received daily in Iran by the Kalbar factory, in addition to meeting domestic needs, has the opportunity to export dairy products to countries such as Afghanistan, Pakistan, Iraq, Syria, Lebanon, Yemen, Oman, Qatar, UAE, Bahrain, Kuwait, Turkmenistan, Azerbaijan, Georgia, Uzbekistan, Tajikistan, Kazakhstan and African countries. As a result, one liter of Kalber UHT milk is also exported in bulk in addition to internal consumption.

Which countries are the primary buyers of Kalber's long-life milk?

The biggest importers of Kalber's long-life milk are Pakistan, Afghanistan, UAE and Iraq, and these countries account for the largest volume of exchanges from Iran.

Advantages and estimated value of aseptic packaging

The market of aseptic packaging and extended shelf life (ESL) is experiencing significant growth, especially in the dairy industry. This innovative technology offers numerous benefits, including long product shelf life and reduced waste, making it a sustainable and cost-effective choice for dairy processors.

Aseptic packaging for dairy products ensures resistance to microbial growth, oxidation, and contamination, making it increasingly popular among dairy producers. This technology allows retailers to store products with long sell-by dates, reduce waste and offer fresher products to consumers.

The global aseptic packaging market is growing, valued at an estimated $61.3 billion in 2022, and is expected to reach $147.6 billion by 2032.

Aseptic packaging offers the advantages of transporting and selling product without refrigeration, making it accessible in areas with limited refrigerated storage. It also reduces the carbon footprint during transportation thanks to lightweight packaging materials.

Additionally, aseptic packaging contributes to sustainability by reducing food waste and enabling the use of recyclable materials. For example, Tetra Pak has introduced polymer-based barriers to replace aluminum foils in aseptic cartons and is testing fiber-based barriers for distribution in ambient conditions.

Durability of tetrapack 200 cc Kalber milk

The conditions of storage and shelf life of tetra Pak milk are very important. UHT milk, or sterilized milk, is a staple in many families due to its long shelf life. Unopened cold-pressed milk can last up to six months when stored in a cool, dry place away from direct sunlight. After opening, it is best to use within 5 to 8 days. The magic lies in the ultra-pasteurization process, which raises the temperature of the milk to kill harmful bacteria and extend its shelf life. Tetrapak 200 cc Kalber milk and in general long lasting milk and long time flavored milk of Kalber Dairy have a shelf life of 6 months.

At Kalbar products factory, aseptic packaging is used for uht milk packaging. This type of packaging prevents the absorption of moisture, light and oxygen. This packaging strategy is very effective in maintaining the quality and freshness of milk during the storage period.

Import, Export, and Trading of UHT Milk (long lasting milk)

Among the export tariff codes in the food industry, milk and dairy products hold the highest value share, accounting for about 27%.

The export of Tetrapak sterilized milk (Faradama) in Iran is considered one of the most important industrial and economic activities of the country. Produced using ultra-heat treatment (UHT) technology, this type of milk has a long shelf life and high quality, and comes in Tetra Pak containers that protect the milk from light, air, and microbes.

The advantages of tetrapack sterilized milk export include long shelf life, maintaining quality, and safe and durable packaging.

Iran has become one of the important exporters of this product in the region with the annual production of significant amounts of uht milk. Target markets include neighboring countries, the Middle East, Central Asia, and even some European and African countries.

Challenges of exporting sterilized uht milk can also include global competition, import regulations, logistics issues.

However, due to the high quality of uht milk produced in Iran and the growing demand in international markets, this industry has a high potential for further growth and development.

Annual export of 3000 tons of Kalber dairy products

3000 tons of Kalber dairy products are exported annually to various countries including the Middle East, Africa, CIS and GCC countries.

This company has the experience of exporting uht milk, breakfast uht cream and dairy products to different markets such as Georgia, Iraq, Pakistan, Azerbaijan, Kyrgyzstan, Kazakhstan, Afghanistan, Africa, UAE, Qatar and Amman under the Kalbar brand.

Respecting customer needs, adhering to commitments, using fresh daily milk from farms supervised and controlled by Kalber Company, and sending the product after a complete quarantine period and QC approval under strict factory supervision, while maintaining the quality of export products as a strategic pillar, are some of the key success factors of Kalber. The company offers a wide variety of exported long-lasting milk.

In order to buy or import 200 cc uht milk in bulk, contact the experts of Kalber Group and get the long-lasting milk as soon as possible. For export orders, you can refer to our Contact us page to directly contact the export manager or sales experts.

Frequently Asked Questions

The main ingredients of milk are water, fat, protein, lactose (milk sugar), and minerals (salt). Milk also contains small amounts of other substances such as pigments, enzymes, vitamins, phospholipids (substances with fat-like properties), and gases.

The amounts of major milk constituents can vary significantly between cows of different breeds and between individual cows of the same breed. Therefore, only approximate values can be given for these variations.

Cow's milk consists of about 87% water and 13% dry matter, which is suspended or dissolved in water. Depending on the type of solids and particle size, there are different distribution systems of these in the water phase.

In addition to total solids, the term solids-not-fat (SNF) is used when discussing milk composition. SNF is total solids minus fat. The average content of SNF, according to the table below, is 13.0% total solids minus 3.9% fat, resulting in 9.1% SNF.

| Main constituent | Mean value | Limits of variation |

| water | 87.5 | 85.5-89.5 |

| Total solids | 13.0 | 10.5-14.5 |

| Fat | 3.9 | 2.5-6.0 |

| Proteins | 3.4 | 2.9-5.0 |

| Lactose | 4.8 | 3.6-5.5 |

| Minerals | 0.8 | 0.6-0.9 |

PH value of milk

The pH of normal milk is generally between 6.6 and 6.8, with an average of 6.7 being the most common.

Read More: Application of Artificial Intelligence in the Food Industry: 6 Innovative Approaches

-min.webp)

(2).webp)

.webp)